PRODUCT

Wastewater Treatment Equipment

Research and development by learning from nature.

We propose optimum water treatments according to various situations.

Treatment processes / Operation procedures

Ultra-high-load anaerobic treatment processsuperDepcer

SUPER Depcer is high-speed and ultra-high-load EGSB wastewater treatment equipment which was developed by applying the UASB process anaerobic wastewater treatment equipment developed in the Netherlands. Different from conventional aerobic treatment, this equipment requires no aeration (process in which wastewater is exposed to air by feeding air into wastewater to supply oxygen for microorganisms). Therefore, it is inexpensive. With less conversion into excess sludge, this equipment creates a clean system which recovers most of wastewater as methane gas.

Drastic reduction

In excess sludge

Energy-saving

With no aeration required

High-concentration

Drainage treatment allowed

Saves cost and space

With high-load treatment

Recovery of excess sludge

As methane gas

- [Application examples]

-

- Food processing wastewater

- Textile industry wastewater

- Beverage manufacturing wastewater

- Refinery and dyeing wastewater

- Fermentation and brewery wastewater

- Oil and fat industry wastewater

- Confectionery industry wastewater

- Pulp and paper wastewater

- Chemical industry wastewater

- Other wastewater

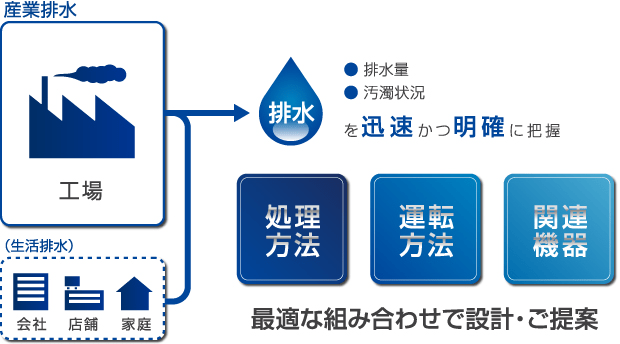

In addition to the above, we propose an optimum treatment process and operation process according to need such as the following.

- Anaerobic fixed bed process (SUPER Depcer FB)

- Anaerobic fluidized sponge bed process (SUPER Depcer SB)

- 2-Step EGSB treatment process

- EGSB + activated sludge treatment process

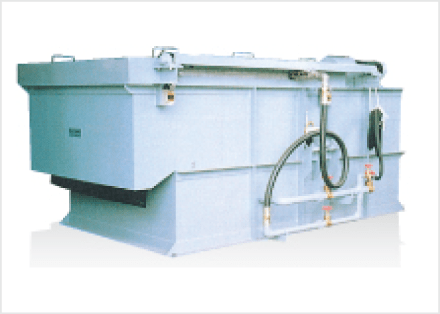

Membrane separation activated sludge methodDepcerMS

Membrane separation activated sludge treatment system is carried out the separation process of activated sludge and treated water in conventional activated sludge method treatment by membrane filtration, and is a system that achieves reliably solid-liquid separation. In addition, it is space saving and low cost, easy to maintenance management, and is industrial wastewater treatment system that achieves to ensure advanced treated water quality. We will select the best one to suit the wastewater by the test evaluation, etc. because there are membranes of various types. Please consult us as a response to the increase of wastewater amount and the changes of water quality by increased production and so on.

| 1 Maintenance management is easy |

|

|---|---|

| 2 Space saving |

|

| 3 Low cost |

|

| 4 High quality treated water |

|

Wastewater Treatment Related Equipment

Wastewater treatment equipment combines and incorporates a variety of related equipment.

Each piece of equipment serves an important role and purpose, therefore we make each piece to maximize the capability of the equipment.

Aiken can build up optimum wastewater treatment systems combining a variety of related equipment and expertise, according to field and application.

In an ever-diversifying industrial society, we always respond to customer need with optimum design and treatment.

- [Product-line examples of related equipment]

-

- Pure oxygen generator

- High-performance solid-liquid separator

- High-pressure belt press dehydrator

- Deodorization equipment

- Rotary screen

- Polydisc type dehydrator

- Pump

- Blower

- Chemical injection equipment

- Pressurized flotation unit

- OHR aerator

- Immersion type MF membrane

- Submerged mixer

- Fluidized sponge bed media

- Fixed bed media

- Heat exchanger